Home

Home

About Geosun

About Geosun

Products

Products

- Hardware

- Mobile LiDAR Scanning System

- gCollector Road Information Collection System

- gSpin POS System

- PPK Solution

Support

Support

News

News

Contact Us

Contact Us

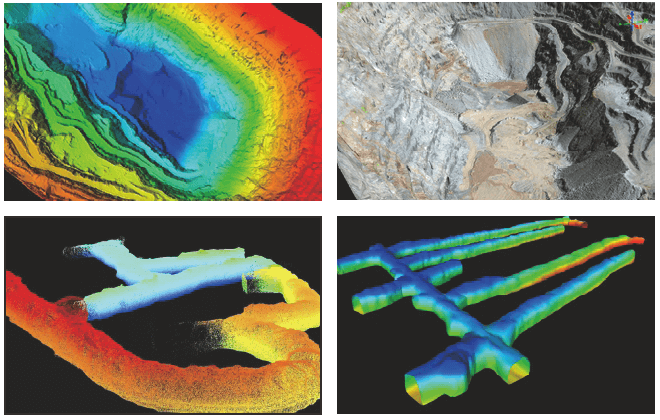

Mining Surveying:

Due to the large open area and deep pits in open-pit mines, traditional surveying methods are time- consuming, labor-intersive, and have safety risks. Using the gAirHawk series of airborne LiDAR systems for data collection in open-pit mines is efficient and accurate. From the collected data, ground points can be extracted to generate contour lines and TIN meshes, as well as produce results such as DEM, DSM,slope, ridge lines, and valley lines.

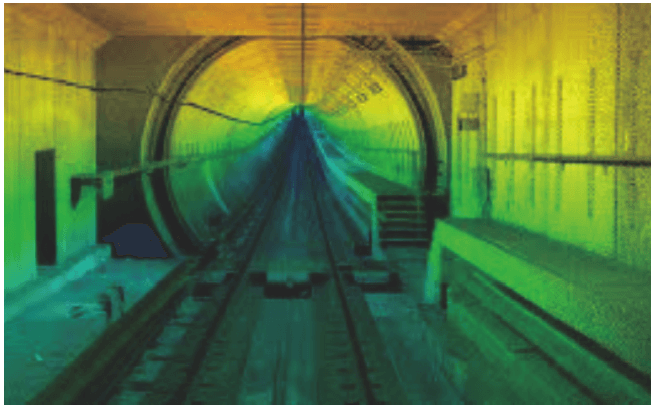

Tunnels Mineshafts:

Due to the large hidden engineering volume, restricted working space, and complex geological conditions of tunnels and mineshafts, traditional surveying methods and instruments are difficult to use for reconstruction and analysis. Regularly using the GS-100G handheld LDAR scanning system for environmental data collection, building a model of the tunnel, and conducting cut-and- fill analysis are of great significance to the safety, quality, and cost control of the project.

Mining Volume Measurement:

During mining operations, it is often necessary to fill in mine pits, and accurate filling volume is required to estimate costs. The traditional volume measurement method uses a total station to survey points, which is inefficient and costly. The GS-100G handheld LiDAR scanning system can quickly establish a 3D data model, from which the filling volume can be calculated.